What Tools Can We Use to Stop Fracking

Extracting gas from shale increases the availability of this resources, just the wellness and environmental risks may be also high.

Point: Yes, it's as well high risk

Natural gas extracted from shale comes at likewise great a toll to the environs, say Robert W. Howarth and Anthony Ingraffea.

Natural gas from shale is widely promoted every bit clean compared with oil and coal, a 'win–win' fuel that tin lessen emissions while notwithstanding supplying abundant fossil free energy over coming decades until a switch to renewable energy sources is made. Just shale gas isn't make clean, and shouldn't be used as a bridge fuel.

Shale rock formations can contain vast amounts of natural gas (which is generally methane). Until quite recently, nearly of this gas was non economically obtainable, because shale is far less permeable than the rock formations exploited for conventional gas. Over the by decade or then, two new technologies have combined to allow extraction of shale gas: 'high-book, slick-water hydraulic fracturing' (also known as 'fracking'), in which loftier-pressure water with additives is used to increase fissures in the rock; and precision drilling of wells that tin can follow the contour of a shale layer closely for iii kilometres or more than at depths of more than ii kilometres (meet 'Fracking for fuel'). Manufacture commencement experimented with these two technologies in Texas virtually 15 years ago. Significant shale-gas production in other states, including Arkansas, Pennsylvania and Louisiana, began only in 2007–09. Exterior North America, only a handful of shale-gas wells accept been drilled.

A drilling operation in Bradford County, Pennsylvania: one of the many places where shale rocks are fractured to release oil and gas. Credit: D. ACKER/BLOOMBERG VIA GETTY

Industry sources claim that they accept used fracking to produce more than than 1 1000000 oil and natural gas wells since the late 1940s. However, less than two% of the well fractures since the 1940s have used the high-volume technology necessary to go gas from shale, near all of these in the past 10 years. This approach is far bigger and riskier than the conventional fracking of earlier years. An average of xx meg litres of water are forced under pressure into each well, combined with large volumes of sand or other materials to help continue the fissures open, and 200,000 litres of acids, biocides, calibration inhibitors, friction reducers and surfactants. The fracking of a conventional well uses at nearly one–2% of the volume of water used to extract shale gas1.

Many of the fracking additives are toxic, carcinogenic or mutagenic. Many are kept secret. In the United States, such secrecy has been abetted by the 2005 'Halliburton loophole' (named after an free energy company headquartered in Houston, Texas), which exempts fracking from many of the nation's major federal environmental-protection laws, including the Safe Drinking Water Act. In a two-hectare site, up to 16 wells can be drilled, cumulatively servicing an surface area of upward to 1.5 square kilometres, and using 300 1000000 litres or more of water and additives. Around i-fifth of the fracking fluid flows back up the well to the surface in the first two weeks, with more continuing to menstruation out over the lifetime of the well. Fracking besides extracts natural salts, heavy metals, hydrocarbons and radioactive materials from the shale, posing risks to ecosystems and public health when these return to the surface. This flowback is collected in open pits or large tanks until treated, recycled or disposed of.

Because shale-gas development is so new, scientific information on the environmental costs is deficient. Only this year have studies begun to appear in peer-reviewed journals, and these give reason for pause. Nosotros phone call for a moratorium on shale-gas development to allow for better study of the cumulative risks to h2o quality, air quality and global climate. Only with such comprehensive noesis can appropriate regulatory frameworks be developed.

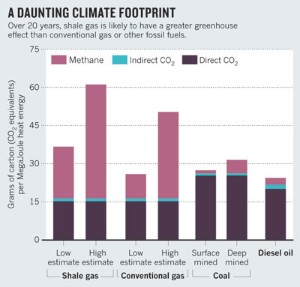

We have analysed the well-to-consumer lifecycle greenhouse-gas footprint of shale gas when used for heat generation (its principal utilize), compared with conventional gas and other fossil fuels — the outset estimate in the peer-reviewed literatureii. Methyl hydride is a major component of this footprint, and we estimate that iii.6–7.nine% of the lifetime production of a shale gas well (compared with i.7–6% for conventional gas wells) is vented or leaked to the atmosphere from the well head, pipelines and storage facilities. In addition, carbon dioxide is released both straight through the burning of the gas for heat, and to a lesser extent indirectly through the process of developing the resource.

Methane is a stiff greenhouse gas, so fifty-fifty small-scale emissions matter. Over a twenty-year time period, the greenhouse-gas footprint of shale gas is worse than that for coal or oil (see 'A daunting climate footprint'). The influence of methane is lessened over longer fourth dimension scales, because methane does not stay in the temper as long equally carbon dioxide. All the same, over 100 years, the footprint of shale gas remains comparable to that of oil or coal.

Credit: SOURCE: REF. ii

When used to produce electricity rather than heat, the greater efficiency of gas plants compared with coal plants slightly lessens the footprint of shale gas3. Even then, the total greenhouse-gas footprint from shale gas exceed those of coal at timescales of less than about fifty years.

Methane venting and leakage can exist decreased by upgrading quondam pipelines and storage systems, and past applying meliorate technology for capturing gas in the 2-week flowback period after fracking. But current economic incentives are not sufficient to bulldoze such improvements; stringent regulation will be required. In July, the US Environmental Protection Bureau released a draft rule that would push industry to reduce at to the lowest degree some methane emissions, in part focusing on mail service-fracking flowback. Still, our analysisii indicates that the greenhouse-gas footprint of shale gas is likely to remain large.

Some other peer-reviewed written report looked at individual water wells near fracking sites4. It found that about 75% of wells sampled inside i kilometre of gas drilling in the Marcellus shale in Pennsylvania were contaminated with methane from the deep shale formations. Isotopic fingerprinting of the methyl hydride indicated that deep shale was the source of contagion, rather than biologically derived methane, which was nowadays at much lower concentrations in water wells at greater distances from gas wells. The study found no fracking fluids in whatever of the drinking-h2o wells examined. This is good news, because these fluids incorporate hazardous materials, and methane itself is not toxic. Even so, methane poses a high hazard of explosion at the levels found, and it suggests a potential for other gaseous substances in the shale to migrate with the methane and contaminate water wells over time.

"Have fracking-render fluids contaminated drinking h2o? Yes."

Accept fracking-render fluids contaminated drinking h2o? Aye, although the show is not every bit potent equally for methane contagion, and none of the information has yet appeared in the peer-reviewed literature (although a series of articles in The New York Times documents the problem, for example http://get.nature.com/58hxot and http://go.nature.com/58koj3). Contamination can happen through blowouts, surface spills from storage facilities, or improper disposal of fracking fluids. In Texas, flowback fluids are disposed of through deep injection into abased gas or oil wells. But such wells are not available everywhere. In New York and Pennsylvania, some of the waste material is treated in municipal sewage plants that weren't designed to handle these toxic and radioactive wastes. Subsequently, at that place has been contamination of tributaries of the Ohio River with barium, strontium and bromides from municipal wastewater treatment plants receiving fracking wastes5. This contamination apparently led to the germination of unsafe brominated hydrocarbons in municipal drinking-water supplies that relied on these surface waters, owing to interaction of the contaminants with organic affair during the chlorination procedure.

Shale-gas development — which uses huge diesel pumps to inject the water — also creates local air pollution, often at dangerous levels. Volatile hydrocarbons such every bit benzene (which occurs naturally in shale, and is a commonly used fracking condiment) are one major concern. The state of Texas reports benzene concentrations in air in the Barnett shale area that sometimes exceed acute toxicity standardshalf dozen, and although the concentrations observed in the Marcellus shale area in Pennsylvania are lower7 (with only ii,349 wells drilled at the time these air contaminants were reported, out of an expected total of 100,000), they are high plenty to pose a risk of cancer from chronic exposure8. Emissions from drills, compressors, trucks and other mechanism can pb to very high levels of ground-level ozone, as documented in parts of Colorado that had not experienced severe air pollution before shale-gas development9.

Unprofitable progress

The argument for continuing shale-gas exploitation often hinges on the presumed gigantic size of the resource. But this may be exaggerated. The Energy Information Administration of the US Department of Energy estimates that 45% of U.s.a. gas supply will come from shale gas by 2035 (with the vast majority of this replacing conventional gas, which has a lower greenhouse-gas footprint). Other gas industry observers are even more than bullish. However, David Hughes, a geoscientist with more than 30 years experience with the Canadian Geological Survey, concludes in his report for the Post Carbon Constitute, a non-turn a profit group headquartered in Santa Rosa, California, that forecasts are likely to be overstated, perhaps greatly then3. Last month, the US Geological Survey released a new gauge of the amount of gas in the Marcellus shale formation (the largest shale-gas germination in the United States), concluding that the Department of Energy has overestimated the resource by some v-fold10.

Shale gas may not be profitable at current prices, in part because production rates for shale-gas wells decline far more rapidly than for conventional wells. Although very large resources undoubtedly exist in shale reservoirs, an unprecedented rate of well drilling and fracking would be required to run into the Department of Energy's projections, which might not be economicaliii. If so, the recent enthusiasm over shale gas could soon collapse, like the dot-com chimera.

Meanwhile, shale gas competes for investment with green energy technologies, slowing their evolution and distracting politicians and the public from developing a long-term sustainable free energy policy.

With fourth dimension, perhaps engineers can develop more advisable ways to handle fracking-fluid render wastes, and perhaps the applied science tin can be made more sustainable and less polluting in other means. Meanwhile, the gas should remain safely in the shale, while guild uses energy more than efficiently and develops renewable energy sources more aggressively.

Counterpoint: No, it's too valuable

Fracking is crucial to global economic stability; the economic benefits outweigh the environmental risks, says Terry Engelder.

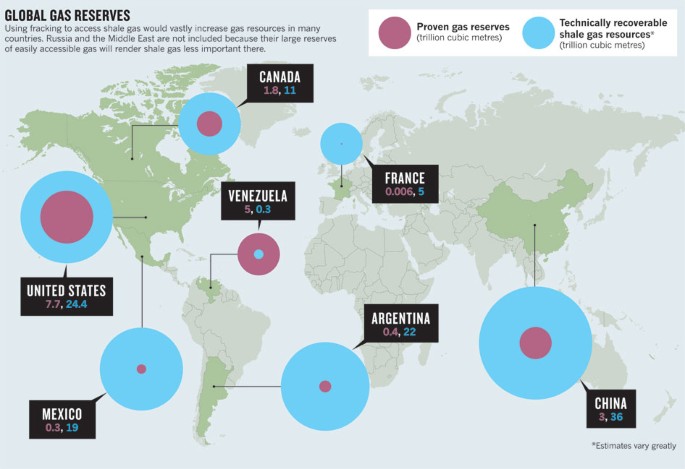

Afterwards a career in geological research on one of the globe's largest gas supplies, I am a built-in-again 'cornucopian'. I believe that there is enough domestic gas to meet our needs for the foreseeable future thanks to technological advances in hydraulic fracturing. Co-ordinate to IHS, a business organisation-information company in Douglas Canton, Colorado, the estimated recoverable gas from Usa shale source rocks using fracking is nearly 42 trillion cubic metres, almost equal to the full conventional gas discovered in the United States over the by 150 years, and equivalent to about 65 times the current US annual consumption. During the past three years, almost 50 billion barrels of additional recoverable oil have been constitute in shale oil deposits — more than twenty% of the full conventional recoverable United states oil resource. These 'tight' oil resource, which too require fracking to access, could generate 3 million barrels a day by 2020, offsetting ane-third of current oil imports. International information aren't as well known, but the effect of fracking on global energy production volition exist huge (meet 'Global gas reserves').

SOURCE: EIA

Global warming is a serious issue that fracking-related gas production can help to alleviate. In a earth in which productivity is closely linked to energy expenditure, fracking will be vital to global economic stability until renewable or nuclear energy carry more than of the workload. But these technologies confront persistent problems of intermittency and lack of power density or waste disposal. Mankind's inexorable march towards 9 billion people will require a broad portfolio of free energy resources, which can be gained but with breakthroughs such as fracking. Such breakthroughs should exist promoted past policy that benefits the economy yet reduces overall greenhouse-gas emissions. Replacing coal with natural gas in ability plants, for example, reduces the plants' greenhouse emissions past up to 50% (ref. 1).

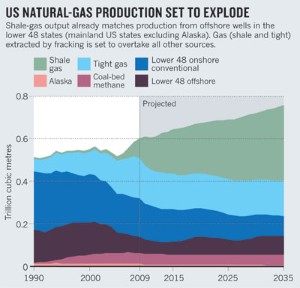

At present, fracking accounts for l% of locally produced natural gas (run across 'US natural-gas production set to explode') and 33% of local petroleum. The gas manufacture in America accounts for US$385 billion in directly economic action and nearly 3 million jobs. Because gas wells have notoriously steep production declines, stable supplies depend on a steady rate of new well completions. A moratorium on new wells would accept an immediate and harsh effect on the US economic system that would trigger a global ripple.

Credit: SOURCE: US EIA Almanac ENERGY OUTLOOK 2011

Global warming aside, there is no compelling environmental reason to ban hydraulic fracturing. There are ecology risks, simply these tin be managed through existing, and rapidly improving, technologies and regulations. It might be nice to have moratoria afterwards each quantum to study the consequences (including the disposal of one-time batteries or nuclear waste), merely considering energy expenditure and economic wellness are so closely linked, global moratoria are not practical.

The gains in employment, economics and national security, combined with the potential to reduce global greenhouse-gas emissions if natural gas is managed properly, make a compelling instance.

No need for panic

"With hydraulic fracturing, equally in many cases, fearfulness levels exceed the evidence."

I grew upwardly with the sights, sounds and smells of the Bradford oil fields in New York land. My parents' small farm was over a pocket-sized oil puddle, with fumes from unplugged wells in the air and small oil seeps coating notwithstanding waters. Earlier college, I worked these oil fields every bit a roustabout, mainly cleaning pipes and casings. Like me, almost people living in such areas are not opposed to drilling, information technology seems. In my experience, such as during the recent hearings for the Pennsylvania Governor's Marcellus Shale Informational Commission, activists from non-drilling regions outnumber those from drilling regions past approximately two to ane.

Mod, massive hydraulic fracturing is very unlike from that used decades ago. Larger pads are required to accommodate larger drill rigs, pumps and h2o supplies. People usually infer from this that modern techniques take a greater impact on the environment. This isn't necessarily true. Although more h2o is used per well, there are far fewer wells per unit of measurement area. In the Bradford oil fields in the 1950s, a 640-acre parcel of land might have held more than 100 wells, requiring some 18 kilometres of roads, and with a lattice of surface pipelines. During the Marcellus evolution today, that same package of land is served by a single pad of five acres, with a 0.viii-kilometre right-of-fashion for roads and pipelines.

Although 'fracking' has emerged as a scare term in the press, hydraulic fracturing is non so strange or frightening. The process happens naturally: high-force per unit area magma, h2o, petroleum and gases deep inside Earth tin can crevice rock, helping to bulldoze plate tectonics, rock metamorphism and the recycling of carbon dioxide betwixt the pall and the atmosphere.

Oil and gas have their origins in muds rich with organic affair in low-oxygen water bodies. Over millions of years, some of these deposits were cached and 'cooked' in the deep Earth, turning the organic matter into fossil fuel and the mud to shale rocks. In many areas, natural hydraulic fracturing allowed a large portion of oil and gas to escape from the dense, impermeable shale and drift into neighbouring, more than porous rocks. Some of this fossil fuel was trapped by cap rock, creating the conventional reserves that mankind has long tapped. The groundwater to a higher place areas that host such conventional deposits naturally contains methane, cheers to natural hydraulic fracturing of the rock and the upward seeping of gas into the water table over long time periods.

More than 96% of all oil and gas has been released from its original source rocks; industrial hydraulic fracturing aims to mimic nature to access the residue. As in nature, industrial fracking can be done with a wide variety of gases and liquids. Nitrogen can be used to open cracks in the shale, for case. Only this is inefficient, because of the free energy lost by natural decompression of the nitrogen gas. Water is more efficient, because very little energy is wasted in decompression. Sand is added to prop open up the cracks, and compounds such every bit surface-tension reducers are added to improve gas recovery.

Nether command

Two main environmental concerns are water use and water contamination. Millions of gallons of h2o are required to stimulate a well. In Pennsylvania, high rainfall means that water is abundant, and regulations ensure that operators stockpile rainwater during the wet season to utilize during drier months (thus the injection of massive volumes of water in the Bradford oil fields for secondary recovery of oil, once the well pressure has fallen, flew under the radar of environmentalists for half a century). Obtaining adequate h2o for industrial fracking in dry regions such as the Middle East and western China is a local concern, but is no reason for a global moratorium.

Press reports often repeat strident concerns nearly the chemicals added to fracking fluids. Simply many of these compounds are relatively benign. One commonly used additive is like to simethicone, which is also used in antacids to reduce surface tension and turn small-scale bubbles in the tum into larger ones that can motility along more hands. Many of the industrial additives are common in household products. Material safe data sheets for these additives are required by US regulation. Industry discloses additives on a website called FracFocus.org, run by state regulators.

Some people take expressed worries that fracking fluids might migrate more than 2 kilometres upwardly from the croaky shale into groundwater. The Footing Water Protection Council, a non-profit national clan of country groundwater and clandestine-injection control agencies headquartered in Oklahoma Urban center, has institute no instance in which injected fluid contaminated groundwater from beneathii. This makes sense: water cannot flow this distance uphill in timescales that thing. This is the premise by which deep disposal wells, used to concur toxic waste material worldwide, are considered prophylactic. During gas production, the pressure of methyl hydride is reduced: this promotes downwards, not upward flow of these fluids.

Gas shale contains a number of materials that are carried back up the pipe to the surface in flowback water, including salts of barium and radioactive isotopes, that might be harmful in concentrated course. Co-ordinate to a contempo New York Times analysis, these elements can be above the US Environmental Protection Agency'southward sanctioned background concentrations in some flowback tanks. Industry is moving towards complete recycling of these fluids so this should exist of less concern to the public. However, production h2o will go on to period to the surface in modest volumes throughout the life of a well; this water needs to be, and currently is, treated to ensure safe disposal.

The real hazard of h2o contagion comes from these flowback fluids leaking into streams or seeping downwards into groundwater after reaching the surface. This can be acquired past leaky wellheads, holding tanks or blowouts. Wellheads are made sufficiently safe to prevent this eventuality; property tanks tin exist made secure; and blowouts, while problematic, are like all accidents caused by human error — an unpredictable risk with which society lives.

Although methane coming upwards to the surface within the steel well pipe cannot escape into the surrounding rocks or groundwater, it is possible that the cement seal between the well and the bedrock might permit methyl hydride from shallow sandstone layers (rather than the reservoir deep beneath) to seep up into groundwater. Methane is a tasteless and odourless component of groundwater that tin can be consumed without ill event when dissolved. Information technology is non a poison. Long before gas-shale drilling, regulators warned that enclosed spaces, such every bit houses, should be properly ventilated in areas with naturally occurring methane in groundwater.

An alarm has been sounded as well about the effect of escaped methane on global warming. The good news is that methane has a very short half-life in the atmosphere: carbon dioxide emitted during the edifice of the first Sumerian cities is nonetheless affecting our climate, whereas escaped methane from the fracturing of the Barnett shale in 1997 is more than than half gone. Manufacture can and should take steps to reduce air emissions, by capturing or flaring marsh gas and converting motors and compressors from diesel fuel to natural gas.

Risk perception is ultimately subjective: facts are all too hands combined with emotional responses. With hydraulic fracturing, equally in many cases, fright levels exceed the evidence.

References

-

New York State Department of Environmental Conservation Revised Draft SGEIS on the Oil, Gas and Solution Mining Regulatory Programme (Sept. 2011); bachelor at: http://go.nature.com/yzponk

-

Howarth, R. Westward., Santoro, R. & Ingraffea, A. Clim. Change 106, 679–690 (2011).

-

Hughes, D. Will Natural Gas Fuel America in the 21st Century? (Mail Carbon Constitute, 2011); bachelor at: http://go.nature.com/gkboqm

-

Osborn, Due south. G., Vengosh, A., Warner, N. R. & Jackson, R. B. Proc. Natl Acad. Sci. United states 108, 8172–8176 (2011).

-

Volz, C. D. et al. Contaminant Characterization of Effluent from Pennsylvania Brine Treatment Inc., Josephine Facility Being Released into Blacklick Creek, Indiana Canton, Pennsylvania (2011); bachelor at: http://go.nature.com/5otd59

-

Texas Commission on Ecology Quality. Barnett Shale Formation Area Monitoring Projects (2010); available at: http://become.nature.com/v7k4re

-

Pennsylvania Department of Environmental Protection. Northeastern Pennsylvania Marcellus Shale Brusk-Term Ambient Air Sampling Report (2011); available at: http://go.nature.com/tjscnt

-

Talbott, E. O. et al. Environ. Res. 111, 597–602 (2011).

-

Colorado Department of Public Wellness and Surround. Public Wellness Implications of Ambience Air Exposures as Measured in Rural and Urban Oil & Gas Development Areas — an Analysis of 2008 Air Sampling Data (2010); bachelor at: http://go.nature.com/5tttna

-

Coleman, J. L. et al. Assessment of Undiscovered Oil and Gas Resources of the Devonian Marcellus Shale of the Appalachian Basin Province, 2011. US Geological Survey Fact Canvass 2011–3092 (2011); available at http://become.nature.com/8kejhm

-

Jiang, Thousand. Environ. Res. Lett. half dozen, 034014 (2011).

-

Statement of Scot Kell, on behalf of the Ground H2o Protection Quango, to the Firm Commitiee on Natural Resources Subcommitee on Energy and Mineral Resources (iv June 2009); available at: http://go.nature.com/5jl2bp

Author information

Affiliations

Corresponding authors

Ethics declarations

Competing interests

Over more than 40 years, T.E.'s enquiry on fracking has been supported past US government agencies including the NSF, DOE, RPSEA, NETL, NYSERDA, EPRI, GRI, NRC, USGS, and PA-DCNR. Industry back up has come from Purple Dutch Shell, Total, Elf, Agip, Texaco, Shell The states, Exxon, ARCO, Mobil, Chevron, Chesapeake, Range Resources, CNX, Talisman, Samson, Southwestern, Encana, Hess and Schlumberger. He has also consulted for manufacture nationally and internationally.

Rights and permissions

About this article

Cite this commodity

Howarth, R., Ingraffea, A. & Engelder, T. Should fracking cease?. Nature 477, 271–275 (2011). https://doi.org/10.1038/477271a

-

Published:

-

Issue Date:

-

DOI : https://doi.org/ten.1038/477271a

Further reading

Source: https://www.nature.com/articles/477271a